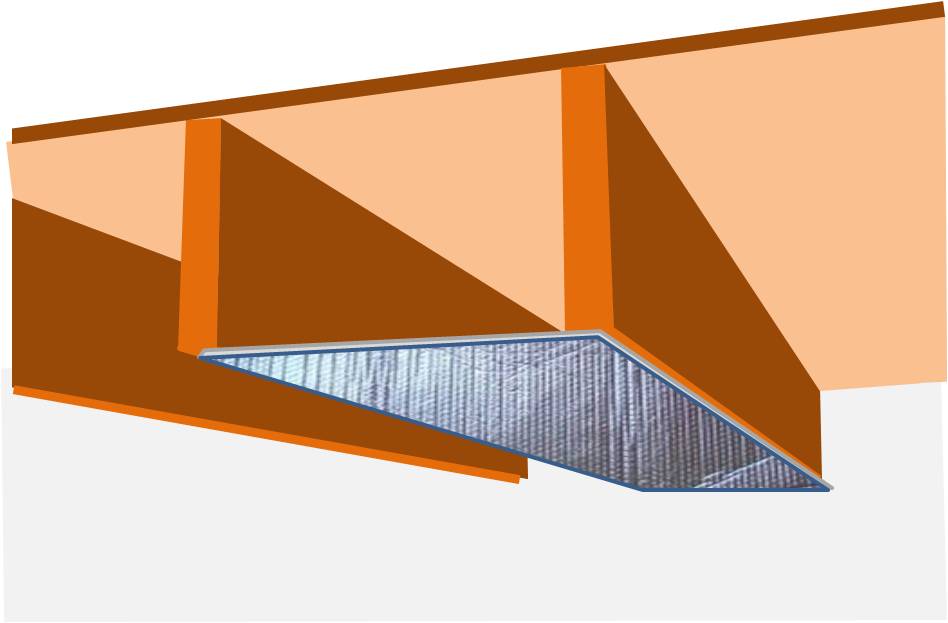

Floor Joist Panning

Master flow 16 in.

Floor joist panning. I am looking for an alternative to replace joist panning that is easier to seal and better all around. 16 in width is equal to the distance of joist spacing allowing the panning to be nailed or screwed directly into the wood. Joist panning lining seems to still be popular. It also can be nailed on the bottom of floor joists to convert floor joist cavities to a duct run.

This panning is constructed with sturdy 30 gauge galvanized steel. This product is proudly made in the usa using galvanized steel construction for durability and rust prevention. It can be cut to size to suit a variety of applications. A two way version of pan joists called the waffle slab uses prefabricated hollow sheet metal domes to create a grid pattern of voids in a solid floor slab saving.

Using floor joists as return ducts by panning can cause leakage because negative pressure in the cavity will draw air from the outside into the cavity through the construction joints of the rim area at the end of the joist cavity. Other articles where pan joist system is discussed. Joist panning can be installed between wall studs to enclose the stud cavity creating a duct run. However a have read in a few places that joist panning is difficult to seal and can pull air from unconditioned spaces.

Still commonly used is the panned floor joist. Female end allows interlocking of multiple pieces for long runs. One is the pan joist system a standardized beam and girder system of constant depth formed with prefabricated sheet metal forms.