Proper Tension For Sewing Vinyl

In this article we discuss everything from the foot to the needle to the stitch length.

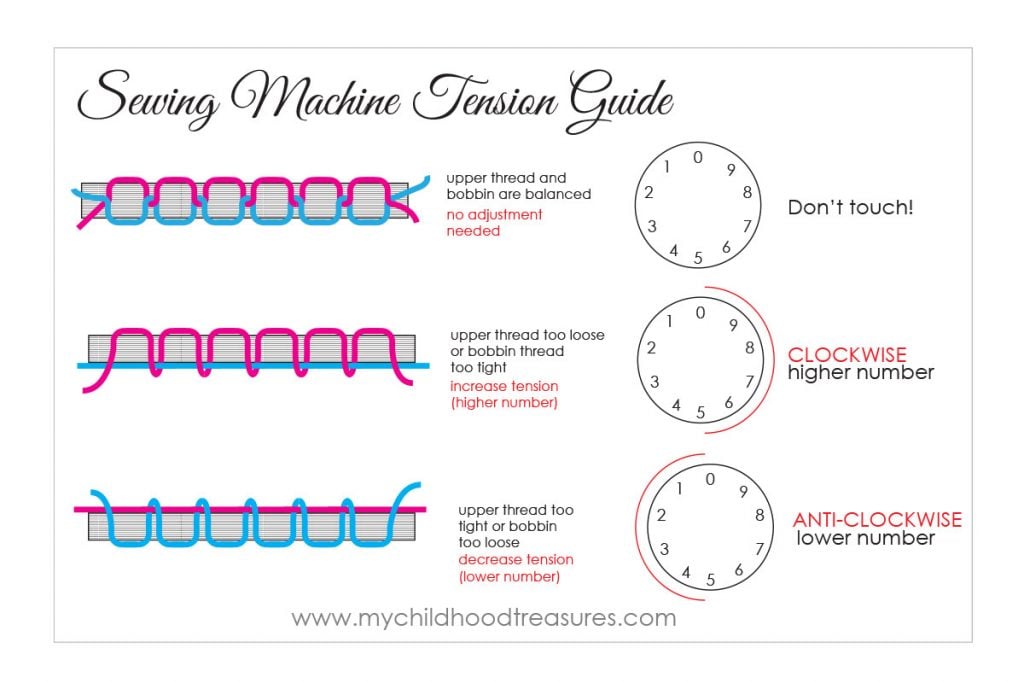

Proper tension for sewing vinyl. As for thread for sewing vinyl on most vinyl you can use general purpose thread but if you expect the seam will experience a bit of a stress use heavy duty thread. The bobbin tension is only a part of the sewing machine tension and must work in conjunction with the needle tension. The trick to sewing vinyl is using the proper tools and adjusting your machine to the proper settings. Sewing machine tension can be tightened or loosened to affect the needle thread the bobbin thread or both.

If the sewing is all wonky on the face top of the fabric and you have ruled out all the possible causes you will have no other way but to adjust this tension. Stitch length for sewing vinyl. Bobbin thread showing on top. Think of your stitching as if there were no thread in the holes created by the sewing machine needle those holes become a tear strip which will weaken the vinyl and make it prone to tearing.

Thread tension that is too loose will cause stitches to unravel while too tight of a tension will cause the fabric to pucker. When sewing with heavy thread you tighten the tension lower bobbin tension adjustment. Balanced machine stitches machine stitches should look the same on both sides of the seam when you sew patchwork pieces together or when you machine quilt through the quilt s top batting and backing. When sewing thick fabrics you tighten the tension.

So make sure the machine is clean and in proper state when starting a vinyl project. Getting just the right amount of tension requires adjusting the tension dial and checking the stitches. Your stitch length when sewing vinyl fabric should be longer than you would use on regular fabric. Sewing with the correct thread tension is necessary for proper stitch formation.

Nylon is the best second best would be 100 polyester.